DP-MASTER

- Details

- Overview

- Design

- Performance

- Features

-

- Commodity name: DPM – MT

The MT Master Torque connection was designed as a high performance rotary shouldered connection for use in very severe drilling operations.

The MT Master Torque connection was designed as a high performance rotary shouldered connection for use in very severe drilling operations.

-

DP – MASTER MT CONNECTIONS

DP – MASTER MT CONNECTIONS

The MT Master Torque connection was designed as a high performance rotary shouldered connection for use in very severe drilling operations.

A well engineered design which evolved from original DPM-DS connection enhanced the mechanical capabilities while still retaining the principle of cost efficiencies in DPM-MT connection.

Thanks to increased torsional strength, the DPM-MT connection delivers superior performance in Extended Reach Drilling (ERD), High Pressure High Temperature (HPHT) and Ultra Deep Drilling. -

Designed for most challenging drilling operation while maintaining the ease of use and repair economics

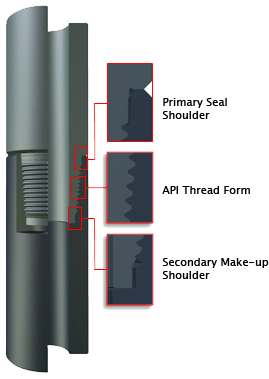

- API taper and thread form to allow easy and quick make-up

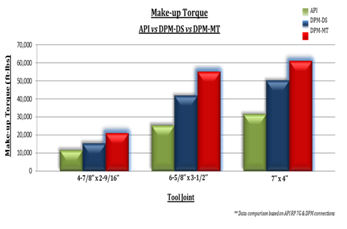

- Double shoulder design provides additional strength to sustain higher make-up torque

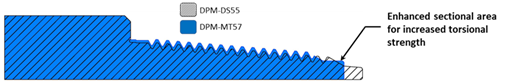

- Added steel at critical areas for increased torsional strength

- Robust yet simple design for operator friendliness and economical over the life cycle

- Cost effectiveness through minimum tool joint re-cut loss, lesser stabling damages and readily available cutting tools in the market

-

DPM-MT connections were subjected to stringent engineering, quality reviews and tests by independent industry recognised agencies to ensure of its highest performance at all levels.

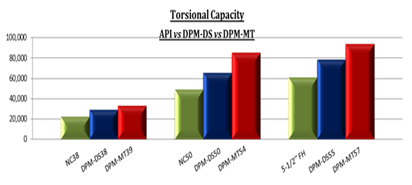

- Substantial increase in torsional strength for high torque applications without significant difference in fatigue performance when compared with equivalent single shoulder connection.

- Tool joint OD / ID streamlined for optimum hydraulic efficiency and fishing ability without compromising torsional capacity

- Smooth internal bore across secondary make-up shoulder to allow smoother fluid flows with minimized turbulence and energy loss inside the connection

- Longer service life due to less stabbing damages and minimum tool joint re-cut loss

- Running speed similar to API connections to save valuable rig time through API taper allowing deeper stabbing and no cumbersome alignment tools needed at stabbing or spinning.

-

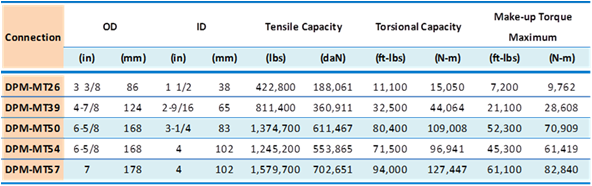

DPM-MT connection is currently available in drill pipe sizes from OD 2-3/8’’ to 6-5/8’’. Other sizes are available upon request. The connection is also available in a wide range of steel grades including sour service and high strength.

Specially engineered using proprietary steel chemistries and state of the art quench & temper process to meet the stringent requirements of IRP 1.8 specification for critical sour drilling

DP-Master offers pup joints and rotary subs to compliment the drill string. A complete range of drilling subs, floor subs and pump-in subs are manufactured in accordance with industry standard or clie

DP-Master manufactures the complete range of API drill pipe products from 2 3/8” OD to 6 5/8” OD in Range 2 and Range 3 sizes up to 48 feet in length.

DP-Master manufactures heavy weight drill pipe from 2 7/8” OD to 6 5/8” OD in Range 2 and Range 3 lengths. HWDP can be supplied either in Conventional Friction Welded or Integral design in accordance

FEEDBACK