DP-MASTER

Heavy Weight Drill Pipe

Category:

Key words:

Drill pipe, weighted drill pipe, drill string accessories, anti-sulfur service

- Details

- Overview

- Standard - Spiral

- Features + Options

- Mechanical behavior

-

- Commodity name: Heavy Weight Drill Pipe

- Commodity ID: 2201

DP-Master manufactures heavy weight drill pipe from 2 7/8” OD to 6 5/8” OD in Range 2 and Range 3 lengths. HWDP can be supplied either in Conventional Friction Welded or Integral design in accordance

DP – MASTER HEAVY WEIGHT DRILL PIPE

DP-Master manufactures heavy weight drill pipe from 2 7/8” OD to 6 5/8” OD in Range 2 and Range 3 lengths. HWDP can be supplied either in Conventional Friction Welded or Integral design in accordance with API Spec 7-1 and NS-1 specifications. HWDP can be supplied in supplied in Conventional Slick or Spiralled forms. Apart from standard API and NS-1 grades, DP-Master can supply Sour Service HWDP in friction welded or integral form.

-

DP – MASTER HEAVY WEIGHT DRILL PIPE

DP-Master manufactures heavy weight drill pipe from 2 7/8” OD to 6 5/8” OD in Range 2 and Range 3 lengths. HWDP can be supplied either in Conventional Friction Welded or Integral design in accordance with API Spec 7-1 and NS-1 specifications. HWDP can be supplied in Conventional Slick, Spiralled or Tri-Spiral forms. Apart from standard API and NS-1 grades, DP-Master can supply Sour Service HWDP in friction welded or integral form.

-

STANDARD HEAVY WEIGHT DRILL PIPE

DP-Master standard heavy weight drill pipe assembly is made up of pin and box tool joints and a heavy weight tube with center upset or wear pad.

This configuration helps to prevent stress concentration which could otherwise occur and allows directional drilling with controlled torque and reduce differential pressure sticking.

The service life of the HWDP is extended to maximize your investment by;

• Providing extra-long tool joint that increases tong space which allows more connection recuts.

• Reducing wear rate on tube OD through additional protection by the center upset or wear pad which keep the tube away from the hole.

HEAVY WEIGHT SPIRAL DRILL PIPE

DP-Master heavy weight spiral drill pipe handles maximum stresses induced at tough drilling environments in vertical and directional wells.

The heavy weight spiral drill pipe shares many of the same features from the standard heavy weight drill pipe except that the pipe body has an enlarged center section with three spiral grooves.

The spiral design adds following advantages;

• Better reduction in differential sticking.

• Increased weight and stiffness.

• Minimizes wear.

• Improves cutting circulation for better hole cleaning. -

ENHANCED FATIGUE RESISTANCE

Cold rolling on the thread roots of every connection is necessary to increase the connection’s ability to resist failure from cyclic stresses on the thread roots when stiffer heavy weight drill pipe undergoes repeated severe tensile and compressive stresses at drilling operation.

Cold rolling hardens the thread roots inducing compressive stress that minimise crack forming to increase fatigue resistance.

API Bore back on the box connection or stress relief groove on the pin connection can further enhanced fatigue resistance on conventional API connections.

Cold Rolling Hardens Thread Root Inducing Compressive Stress that Minimise Crack Forming To Increase Fatigue Resistance

HIGH PERFORMANCE ROTARY SHOULDER CONNECTIONS

DP-Master offers its DS and MT series double shoulder connections which outperform conventional API connections to meet the needs of deep, extended and challenging wells with greater torsional capacities.

INCREASE DRILL PIPE LIFE

Hardbanding on the tool joint or wear pad extends the service life of drill pipe. It can be applied in several configurations to suits clients requirements.

Hardbanding is applied under closely controlled conditions resulting in a uniform, low porosity, wear resistant surface.

DP-Master is authorised to apply market proven hardbanding products including ARNCO 100XT / 300XT, Tuboscope TCS8000 / TCSTI, Duraband NC, Tuffband NC and Castolin OTW 12.

Extra length tool joints are incorporated into DP-Master heavy weight drill pipe to increase tong space to provide several recut to the connections.

SURFACE PROTECTION

Phosphate coating are applied to all heavy weight drill pipe connections to improve anti galling and corrosion.

DP-Master can supply heavy weight drill pipe with any market available internal plastic coating. The coating forms a protective layer in the pipe ID to prevent corrosion and thus extend the life span of the pipe in the drilling environment. -

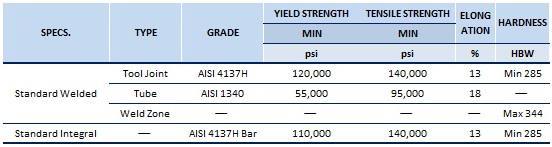

DP-Master standard heavy weight drill pipe tube is manufactured from AISI 1340 steel or equivalent while the tool joints are supplied with AISI 4137H modified alloy steel material.

Another option of heavy weight drill pipe in integral can be supplied upon request.

All DP-Master steel tubes are procured from reputable bar supplies with strong quality track records.

DP-MASTER HEAVY WEIGHT DRILL PIPE GRADES TABLE

Specially engineered using proprietary steel chemistries and state of the art quench & temper process to meet the stringent requirements of IRP 1.8 specification for critical sour drilling

DP-Master offers pup joints and rotary subs to compliment the drill string. A complete range of drilling subs, floor subs and pump-in subs are manufactured in accordance with industry standard or clie

DP-Master manufactures the complete range of API drill pipe products from 2 3/8” OD to 6 5/8” OD in Range 2 and Range 3 sizes up to 48 feet in length.

DP-Master manufactures heavy weight drill pipe from 2 7/8” OD to 6 5/8” OD in Range 2 and Range 3 lengths. HWDP can be supplied either in Conventional Friction Welded or Integral design in accordance

FEEDBACK